Bearings are critical components in machinery, requiring precise lubrication to reduce friction and wear. Memolub provides advanced lubrication solutions designed to deliver consistent and accurate amounts of lubricant. Our systems help in preventing overheating and bearing failure, ensuring smooth operation and extended lifespan. Trust Memolub to maintain the reliability and efficiency of your bearings.

Bearings

Affordable automatic lubrication for 84 critical stacker bearings.

An extruder in a tire factory.

Automatic lubrication in a French fries factory.

Automatic lubrication upgrade for Skako motovibrators

Automating lubrication for hospital laundry machine bearings.

Automating lubrication for water gate infrastructure.

Automating lubrication in metal packaging production for enhanced efficiency.

Ball mills at a gold processing facility.

Cleanroom fans at an incontinence material factory.

Conveyors and blower fans at a building waste recycling plant.

Electro-motor driven pumps in a waste incinerator.

Eliminating human error in lubrication for chamfering machine spindle bearings.

Enhancing bearing reliability in a noodle production plant.

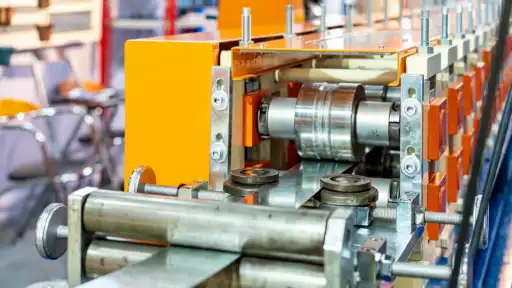

Enhancing efficiency in steel rolling mills

Enhancing maintenance efficiency in a water treatment facility.

Enhancing vertical turbine efficiency with automated lubrication.

Ensuring consistent lubrication for Rollix bearings.

How a quarry reduced maintenance costs and downtime on a mobile crusher.

Lubricate the bearings of a mine stacker.

Lubrication of the bearings of a single and double cable drum twister.

Lubrication of the lower bearings of a coil accumulator.

Lubrication of the propeller shaft bearing and the clutch of a truck.

Nodding donkeys at an oil well.

Optimizing wind turbine blade lubrication.

PLC driven lubrication with visual feedback on a steel pipe stacker.

Reduced maintenance and improved reliability for a metallurgy and wire-drawing player.

Securing motor bearing reliability in lumber dryers.