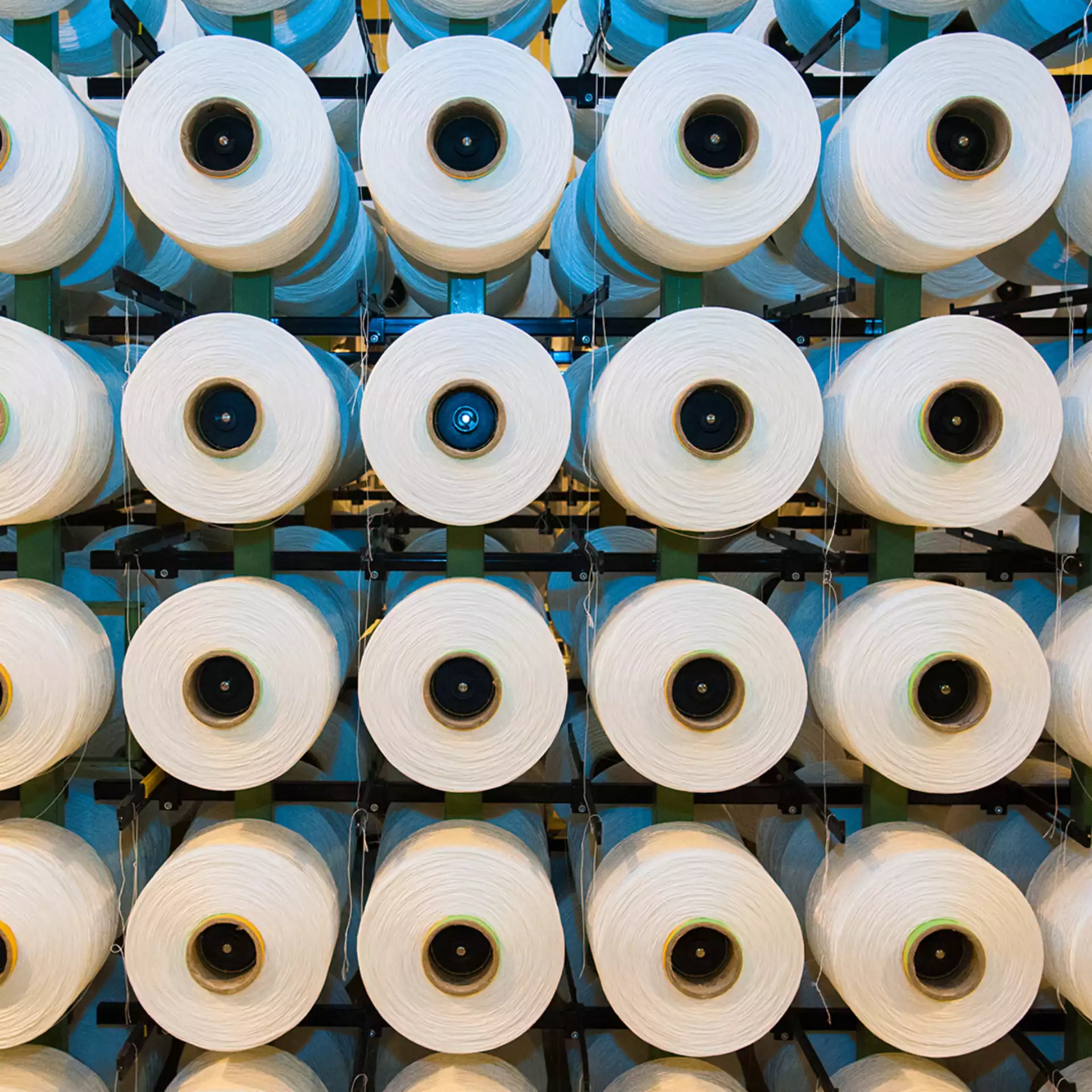

Memolub provides specialised lubrication solutions that cater specifically to the high demands of the textile industry, encompassing all stages from raw material processing to weaving and finishing. Our systems are designed to handle the aggressive environments commonly found in textile manufacturing, ensuring that machines operate with both speed and precision.