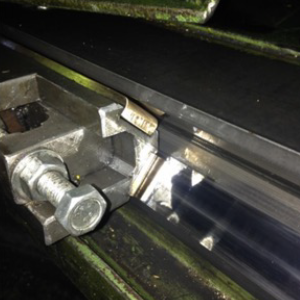

An old automatic lubrications systems takes care of the lubrication of bronze sliders of a German manufactured a wire drawing machine.

MEMOLUB®DS

Decentralised lubrication in a wire drawing mill.

Context

Problem

Managing the right quantity of oil with the old system was very hard, causing many production stops. In case too much oil was used, wires could slip from the clamping jaws. With too little oil used, wires often jammed. In both cases an operator had to stop the machine, make his intervention and restart the wire drawer. Costly, without a doubt.

Solution

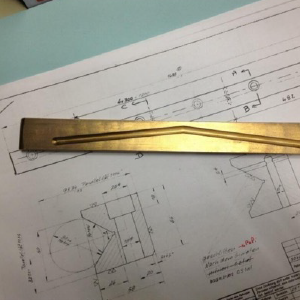

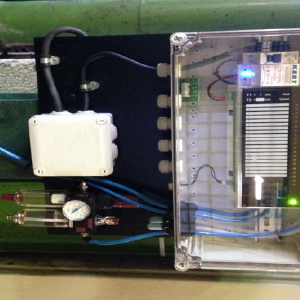

The installation of a MEMOLUB® DS lubrication system, combined with an automatic grease level sensor directly connected to the wire drawer. On top there was the replacement of the previous used oil by a liquid grease from Castrol.

Results

- The machine stops automatically when MEMOLUB® DS detects it has ran out of grease.

- Very stable production process, with no more unforeseen machine stops due to wire jams our slips.

- A clean production line, with no more oil leaking and dripping on the production halls floor.

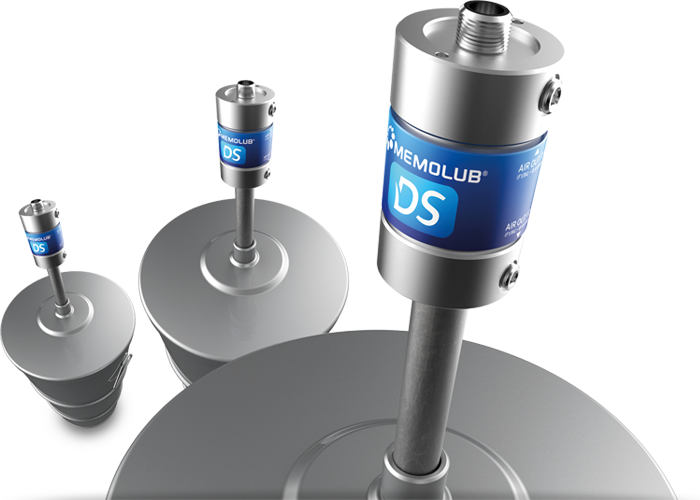

Memolub® DS

- Reusable multi-point lubrication system.

- 24V powered.

- 70 bar ejection pressure.

- Up to 20 outlets.

- Remote installation up to 20m.

- PLC driven settings if desired.

- Flexible pumping cycle settings.