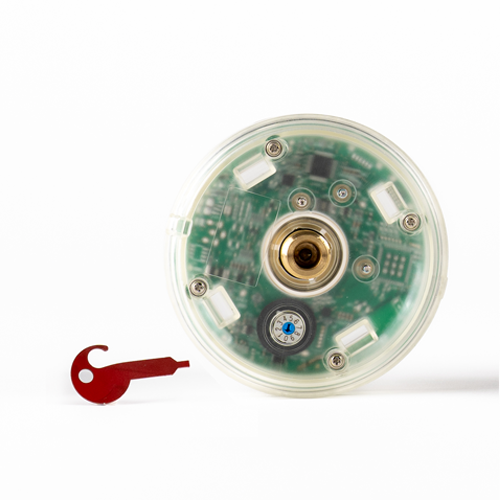

There are 9 main frequency settings available that are suitable for most industrial applications. They are programmed by selecting your preferred setting with the MEMOLUB® VISIO KEY on the MEMOLUB® VISIO MEMO BASE. With the help of stroke washers the amount of lubricant discharged per lube cycle is adjustable. Installing one, or a combination of multiple stroke washers, into the fitting will limit the stroke length of the piston inside the lubricator and leads up to 72 possible frequency/volume settings.

THE RIGHT VOLUME AT THE RIGHT FREQUENCY IS KEY.

A POWERFUL AND EFFICIENT PUMP

The MEMOLUB® VISIO pump is engineered to deliver powerful output pressure (25bar/350psi) and is capable of pumping low- and high viscosity lubricants at extreme temperatures. Thanks to the patented electro-mechanical technology inside MEMOLUB® VISIO, the system is safe for the negative consequences of back-pressure.

Monitoring and visual feedback with AI-driven precision.

Memolub VISIO leverages AI and machine learning to analyse lubricant flow within the pump, detecting issues like system back pressure, clogging, and empty cartridges by monitoring vibration and sound patterns. This advanced analysis allows maintenance teams to closely monitor lubrication across their machine park. When the system identifies a potential issue, visual feedback is provided through integrated LEDs, enabling timely intervention and ensuring optimal performance.

MEMOLUB® OIL R-500 COMPATIBLE

MEMOLUB® OIL R-500 is a refillable 500cc reservoir for oil applications, compatible with MEMOLUB® HPS.

IMPROVED SUSTAINABILITY

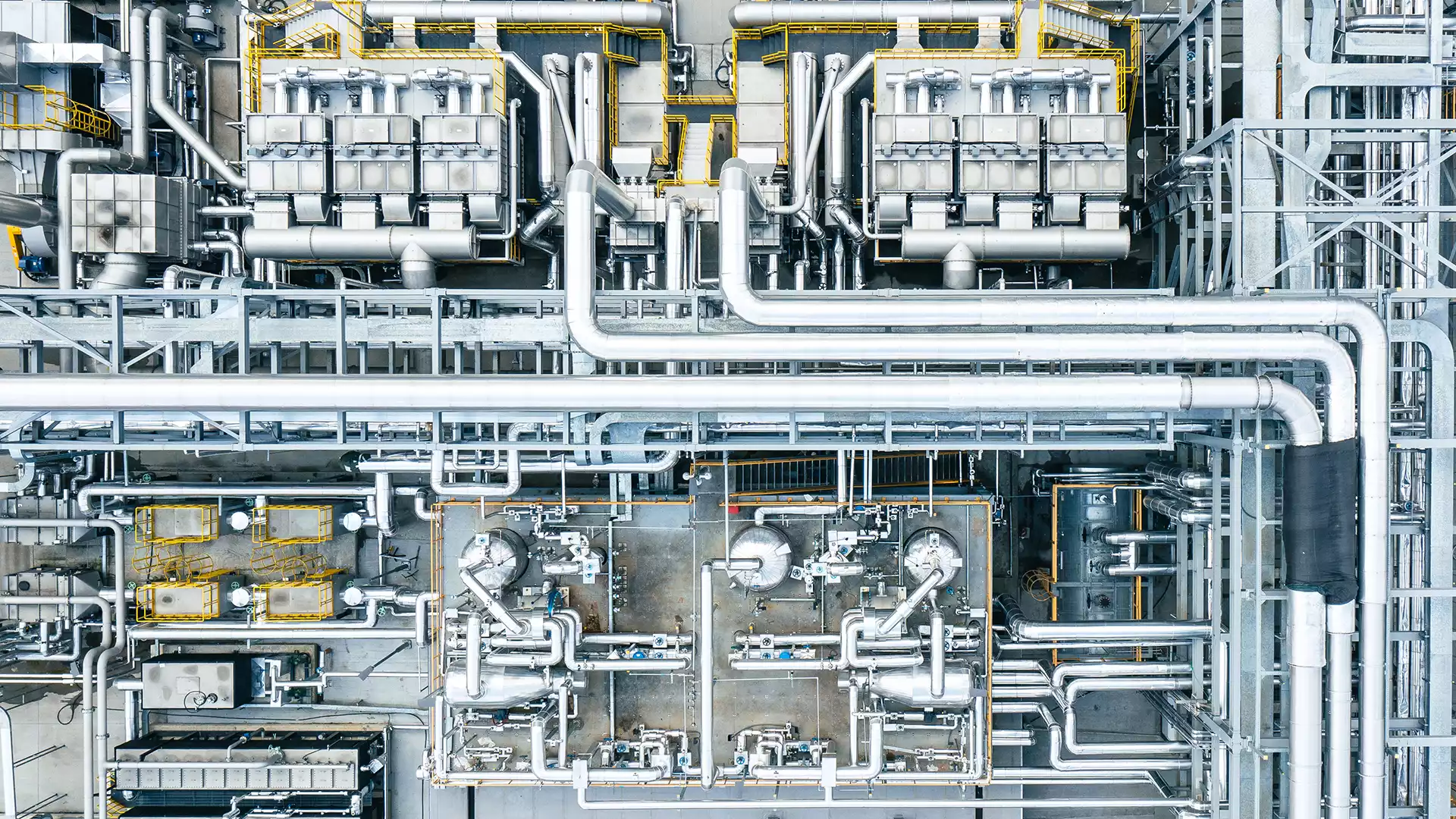

Reduce environmental burden, save on energy, production consumption and easily meet environmental standards and goals.

ECONOMICAL SAVINGS

Savings on installation and implementation costs, low maintenance costs and long-term protection of the mechanical equipment.

FLAWLESS RELIABILITY

Achieve your predetermined production goals, increase safety and maintain the same quality.